Tooling

Until recently, Molded Pulp tooling costs and lead times had been obstacles for some projects. However, here’s the latest news about tooling for Pulp:

- Molded Pulp tooling is now less expensive.

- Low cost prototype tools provide production-quality samples.

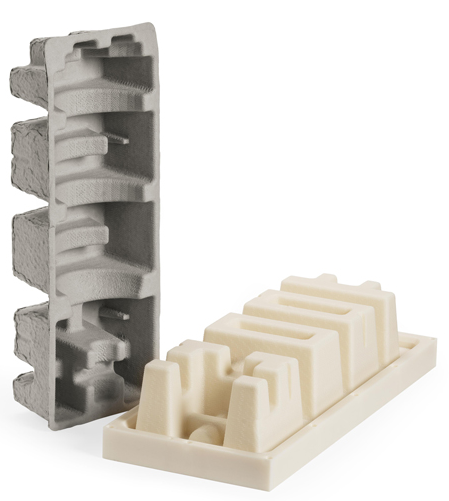

- Molded pulp production tooling is now available as 3-D printed tools.

- Existing molded pulp tooling can be used on our molded pulp system.

- Molded pulp production tooling can now be guaranteed up to five million cycles, extending its lifetime, so costs are reduced over the long term.

- We use a variety of materials for molded pulp tooling.

Single cavity tools for low volume projects.

Pulp Molding Blog

Why is it Important to Recycle?

Recycling is one of the best ways to make a positive impact on the planet. The amount [...]

Why Molded Pulp is a Great Green Alternative

More and more people are becoming aware of the importance of green products. That is why more [...]

Top 3 Ways to Make Your Business More Eco-Friendly

There are so many positives for companies that choose to practice and maintain eco-friendly values. Today’s consumers [...]