More and more people are becoming aware of the importance of green products. That is why more consumers are seeking eco-friendly products and packaging. People are starting to make purchasing decisions based on what companies are using for their products and packaging. It is essential that companies adjust their operation to the use of green products. One of the best alternatives includes the use of molded pulp.

What is Molded Pulp?

Molded pulp is made from a variety of fibrous materials such as recycled:

- Paper

- Cardboard

- Natural fibers (wheat straw, bamboo, sugarcane)

- Newspaper

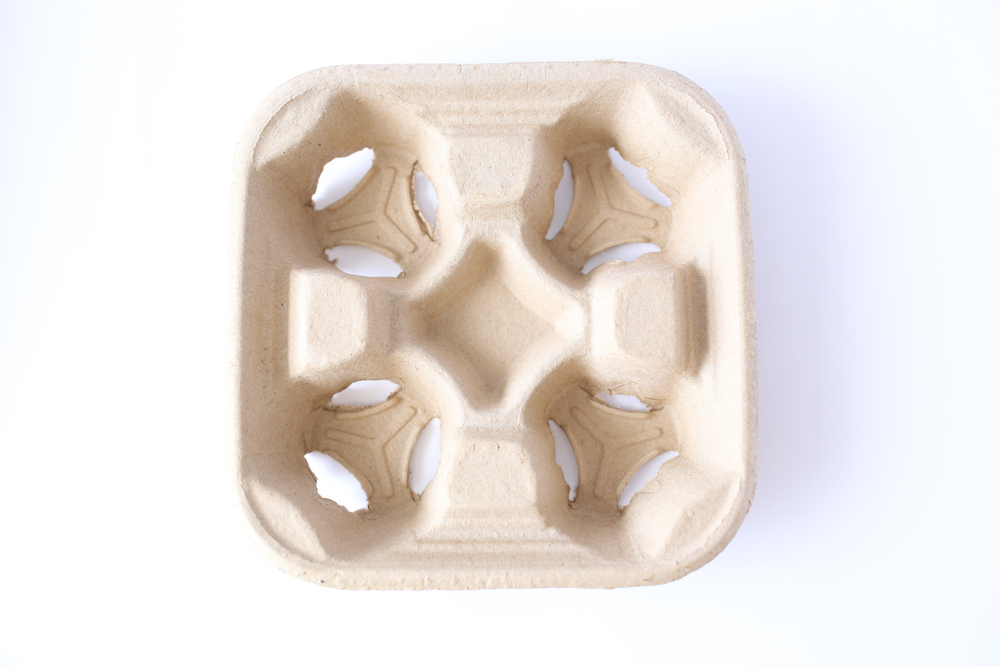

Molded pulp is formed to create a shape that serves a specific purpose, such as trays, cushions, and incaps. Molded Pulp can do almost anything plastic or foam can do – but with the added bonus of being green. This green material can be used to:

- create the actual product

- transporting consumer electronic products such as: household appliances, fragile consumer goods, glass containers, and even eggs

Molded pulp can be engineered to become a solution for almost anything.

Performance

The performance of molded pulp is of great quality as it provides excellent bracing, blocking, and cushioning protection. It is statically neutral, water-resistant, and unaffected by extreme temperatures. It is nestable and stackable, which reduces storage costs by as much as 75%.

Environmental

Molded pulp is manufactured with 100% recycled materials and is recyclable, biodegradable, and compostable. There is no water waste with the production of it as all of the water is evaporated or reused in the pulping process. Zero manufacturing waste results from molded pulp as all scraps are returned to the pulp slurry. The final packaging is 100% recyclable, which means no waste!

Economic

The cost of molded pulp is lower than that of other protective packaging such as foam and thermoformed plastics. It is designed to nest for reduced shipping and storage costs. It is also formed to shape. This means that assembly is not required, thus greatly reducing labor costs.

Benefits

Molded pulp packaging offers a wide range of benefits compared to traditional plastic and foam packaging.

Manufacturing Pulp Packaging

The general manufacturing process of molded pulp requires six steps.

- Step 1: Mixing – The first step consists of soaking the recycled materials in water and mixing them until the right consistency of pulp is achieved. No water waste is generated in the manufacturing process; all excess water either evaporates during manufacturing or is returned to the system

- Step 2: Forming – The pulp is formed into the desired shape or design

- Step 3: Drying – The molded pulp is dried with a high-temperature drying oven

- Step 4: Pressing – To smooth the surface, each product can be pressed onto solid metal tools. In addition to making the pulp parts look better, the pressing improves the stacking and nesting for more efficient storage and shipping.

- Step 5: Trimming – The edges of the parts can be trimmed. No material is wasted as all the cut-offs are returned to the pulp mixture and are re-used

- Step 6: Quality Inspection – Lastly, the molded pulp is inspected for quality. Defects are returned and reused

The need for green alternatives is growing, and molded pulp is a great option. Apart from it being 100% recyclable and green, it is durable and functional. We hope this blog helps you see why molded pulp is a great green alternative. If you decide to incorporate the use of molded pulp into your business, give us a call at (619) 977-5617 or visit our website here.