Products

Whether you’re looking for molded pulp, molded fiber, moulded pulp or molded fibre we manufacture it using only recycled newsprint, recycled corrugated and water. Molded pulp is made with your business in mind to protect, present and sell your product.

Bottle and Glass Shippers

At Pacific Pulp Molding we provide molded fiber solutions for protecting and shipping glass products. We ensure transport safety and meet FedEx and UPS shipping standards. We’ve provided glass shipping solutions for a variety of applications including candles, nutritional supplements, bottles, wine and essential oils.

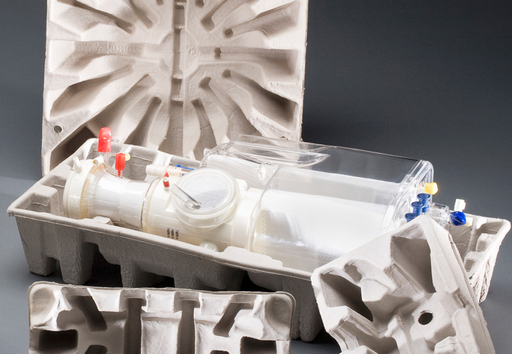

Custom Applications

Our design team begins with your product dimensions, weight and shipping requirements. We then create a design and a prototype tool. On your approval, we make production tooling and begin supplying your molded pulp trays or end caps.

- Audio visual components

- Broadband routers and modems

Endcaps, Clam Shells

- External hard drives

- Home plumbing/faucet

Home hardware, lock sets, security systems

- Household appliances

- Medical/hospital devices

- Navigational devices

- Home office components

- Set top boxes

Sound system components

Molded Pulp Solutions

biznet2025-04-21T14:45:01-07:00

biznet2025-04-21T14:45:08-07:00

biznet2025-04-21T14:45:12-07:00